ESVIN

Advanced Technologies Limited is

involved in the promotion and development of innovative technologies to suit Indian conditions relevant to Pulp & Paper and Sugar Industries.

Have developed applications of Gasification

Technology, Biotechnology & Membrane Technology

specific to Pulp & Paper and Sugar Industries.

Application

of Gasification Technology

Application of low temperature gasification (Indirect Gasification Technology) adopting Thermo Chemical Conversion Reformer (TCCR) System licensed from Manufacturing and Technology Conversion International, Inc. (MTCI), Maryland, USA, for the following fields of application in India:

To recover chemicals from Black Liquor produced in paper mills

To recover chemicals from Black Liquor produced in paper mills

To treat waste sludge from paper mills

To treat waste sludge from paper mills

To treat effluent discharged by distillery units

To treat effluent discharged by distillery units

A demonstration unit of TCCR System was set up at the mill premises of Seshasayee Paper and Boards, Erode, in 1993-94. Since then various trials using Black Liquor, Distillery Spent wash have been carried out. There are two commercial installations – one in Norampac mill in Trenton, Ontario, Canada and the other one is in Georgia Pacific Big Island Mill in Viriginia, USA. Both installations were implemented by ThermoChem Recovery International (TRI), Maryland, USA, who have been granted worldwide license by MTCI, other than India, for application of Black Liquor, Biomass etc., in a paper mill. More details can be had from www.tri-inc.net

|

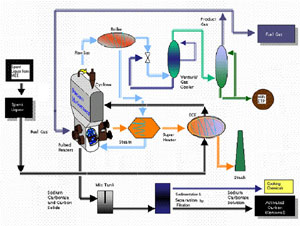

Black

Liquor Chemical Recovery Flow Diagram

(click on the image

for enlarge) |

|

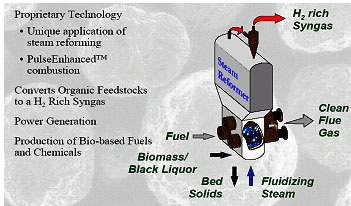

Steam Reformer with 3 - Heaters |

ThermoChem Inc., USA, a marketing arm of MTCI, is currently developing projects for production of liquid Biofuels such as Methanol, DME, Ethanol etc., by converting Biomass to Syngas (CO + H2) which can be further converted in to Biofuels. Taking advantage of this new market segment, namely, Biofuels, Esvin Tech is launching a new thrust for manufacture of Ethanol from Molasses by thermo-chemical conversion rather than by Biochemical conversion (fermentation route), as the former has the unique advantage of avoiding liquid effluent, which otherwise requires to be treated. In other words, this is a classical example of “pollution prevention” process as against the “end of pipeline” solution, which is required to be done for the existing distillery units. Even for these units, Esvin Tech has proposed a System (comprising evaporator, spray dryer and steam reformer) leading to “zero liquid discharge” effluent treatment system.

Application

of Biotechnology

Biotechnology involved development of Bio-pulping, Bio-bleaching and Effluent Decolourisation through microbial culture.

Bio-bleaching was carried out through microbial enzyme and an Indian Patent was obtained for Bio-bleaching process.

This division was hived-off to promote a Company called Esvin Biosystems Limited (EBL) in 1996.

Australian Joint Venture

A Joint Venture Company (JVC) was promoted by EBL with an Australian Company called Biotech International Limited (BIL), Perth, in October 1997 and the JVC was named Esvin Biosys International Limited (EBIL), headquartered in Chennai, India.

Biotech International Limited,(BIL) a leading Pharmaceutical Company, headquartered in Brisbane, had assigned to its !00% subsidiary called Industrial Biosystems Limited, Perth the development of B230 Xylanase Enzyme up to the level of commercial scale.

Development and Commercialization of Enzyme

Development and up scaling of B230 Xylanase Enzyme was carried out by EBIL with fermentation facilities available in and around Chennai.

Commercial manufacture of B230 Xylanase Enzyme was established at the production facility of a leading Enzyme Manufacturer in India.

Mill scale trails with this Enzyme have been successfully completed in few Indian paper Mills since January 2001. But the Indian company could not continue due to change in the Management of BIL and funding problems.

Application

of Membrane Technology

This technology was developed in technical collaboration with a leading confectionery manufacturer in the country for production of Liquid Sugar by adopting Electro dialysis (ED) process. The initial concept of the technology was jointly developed with CSMCRI, one of the CSIR Institutions in India.

Pilot scale testing was successfully carried out at Ponni Sugars by importing the ED stack from France and the Liquid Sugar closely matched International norms.

An Indian patent was obtained jointly in the names of Esvin Tech and the Confectionery manufacturer.

Top

|